Aws Cwi Can Be Fun For Anyone

Aws Cwi Can Be Fun For Anyone

Blog Article

Rumored Buzz on Aws Cwi

Table of ContentsAws Cwi - TruthsAws Cwi for DummiesThe smart Trick of Aws Cwi That Nobody is Talking AboutSome Known Questions About Aws Cwi.Some Ideas on Aws Cwi You Should Know

It needs to be kept in mind that many tasks do not have requirements for utilizing qualified inspectors and lots of firms use their "finest" welders for this duty. While this may work in some instances, it is definitely harmful and it has many defects, some noticeable and some not so obvious. PFS developed a program where all Welding Inspectors are certified based on ASNT SNT TC-1A and AWS QC1 Licensed Welding Inspector.

The duty of All PFS welding inspectors begin before the welding equipment is even switched on. PFS Welding Assessors are educated to inspect the following prior to welding begins: Welder is certified. Base material is suitably clean prior to welding.

The Single Strategy To Use For Aws Cwi

The WPS variables are being followed by the welder. PFS Welding Examiners then examine all welding operations throughout the manufacturing process to make sure that all demands are being fulfilled. The benefits of utilizing Licensed Welding Assessors: ASNT and AWS Welding examiner certification has actually been widely approved by the USA and even a number of the major industrial nations on the planet.

Quality welding and highly educated certified welding evaluations directly influences not just the performance of the item however the security, life span and reliability of the procedure that the bonded component is part of. One component of this, the Qualified Welder, is not nearly enough to make certain success as with any kind of procedure, an independent set of eyes that are educated to establish an appropriate training process as well as a reliable and efficient recorded monitoring system as provided by a Qualified Welding Examiner, completes the high-quality control that makes sure that the customer is offered the finest possible high quality developed and recorded item.

Do not be shocked that many prominent markets will certainly need you to utilize licensed welding inspectors to look after welding - https://sandbox.zenodo.org/records/109873. This is done to minimize risk in what is commonly viewed as a rather high-risk sector. An internal certified welding assessor will certainly have the ability to ensure that your project is customized to all the requirements of relevant welding codes, guaranteeing its quality

Our Aws Cwi PDFs

They'll additionally start the process by carrying out testing tasks like welder efficiency certification screening and welder treatment qualification testing. This generally needs some weeks to finish and require to be assessed and accepted before the onset this hyperlink of clients welding projects. This makes sure the knowledge of those servicing your job.

Licensed in-house welding inspectors give that careful eye. They will help you by removing variability during the welding procedures (http://peterjackson.mee.nu/where_i_work#c2362). This in turn will certainly profit you with a quicker outcome and decreased production costs at the end of stated procedure, allowing you to do more with the resources that you already have

These include ductility, joint geometry, wire feed speed, arc current, arc voltage, base metal chemistry, protecting gas kind, filler metal chemistry, and tensile stamina to call a few. It is very important that you consider the value of having a certified welding inspector before you begin any kind of task. There is a genuine worth in having an expert evaluation your task before you also strike the very first arc.

Indicators on Aws Cwi You Need To Know

A certified welding assessor will certainly have had lots of years of experience which your business will be able to attract from. They will certainly have seen various pitfalls and successes and the lessons they have actually picked up from them will assist your organization to steer clear of from expensive reworks. This is why it is essential to discover a welding company with an experienced and highly educated internal certified welding assessor on personnel.

Something went wrong. Wait a minute and attempt once again Try again.

Since 1919, American Welding Culture requirements, solutions, and programs have actually supported the guys and women of welding in the USA. Today AWS is honored to claim that our impact spans the globe, and we support hundreds of welding specialists worldwide. To aid our international members, AWS agreements with organizations in countries throughout the world to assist in accreditation tests.

This technique of experience-based understanding assists welders in training understand technical market criteria and terms while acquiring essential hands-on skills. Offering this kind of training implies trainees need outstanding aid from certified specialists.

Unknown Facts About Aws Cwi

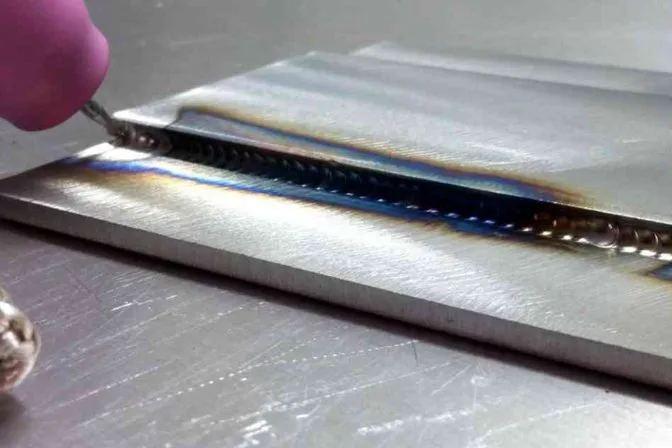

Our weld assessment procedures assist to confirm the top quality and preciseness of welds, while testing methods assist to recognize variances and ineffectiveness. These processes combined impact boosted project efficiency along welders. OXARC's diverse variety of welding refines our experts can evaluate is extensive with processes like: Secured metal arc welding (SMAW) Gas tungsten arc welding (GTAW) Change core arc welding (FCAW) Gas metal arc welding (GMAW) We can also execute qualification and certification tests on plate, pipeline, stainless steel and other particularly requested materials.

Professional management, quality products and solutions and commitment to our sector maintain OXARC providing our consumers with the products and options they require. Our personnel has a straight line of interaction with the professionals in welding such as Lincoln Electric, ESAB, Avesta Stainless, Stoody, Select Arc, Eutectic and Thermal Arc, making our solutions an excellent selection for varied markets.

Report this page